The following list shows some of the supported industrial projects, mainly for major OEMs and T1 suppliers. Applying best practices across industrial domains also in your project will save you time and money (*).

Transportation:

Transportation:

- Identification and acquisition of hazards, hazardous events, safety goals and safety requirements for a pantograph-subsystem of a new locomotive-platform from scratch, using various identification techniques and patterns and covering the various application scenarios and environments.

- Functional and non-functional safety-management support for electrical propulsion-systems of light rail vehicles incl. Verification & Validation, organization of document-flow, system-decomposition and DOORS-based requirements-capturing and -tracking acc. EN50126/EN50128/EN50129; generic platform concepts vs. tailored application system (Germany; see also separate blog article);

- Virtual Engineering evaluation on support of various reliability, safety, maintainability, testability and diagnostic methods, e.g. FMEA, FTA, RBD, CCA in train and infrastructure development/underground stations supply (UK);

- Automated generation of troubleshooting/diagnostic procedures of the Door System of a regional train to reduce MTTR (Mean Time to Repair) based on virtual product descriptions (UK);

Ready to benefit from this experience in your Rail-project? – Get in contact now!

Automotive:

Automotive:

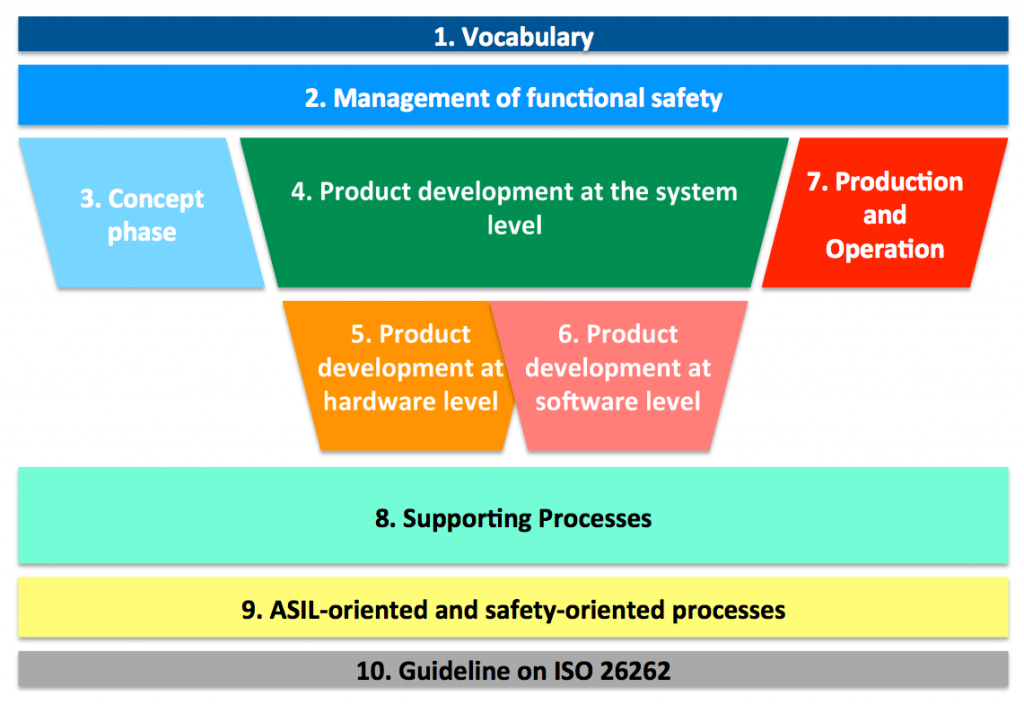

- Safety-Engineering and process-optimization in development of braking systems according ISO26262; Impact analysis, hazard and risk analyis (HARA), functional safety concept and technical safety concept, verification and validation reports; migration of established legacy processes to ISO26262-compliance; safety requirement derivation from safety goals e.g. by “Goal structuring notation” (GSN); generic system templates and workproducts vs. application specific adaptions (Germany, US); see also –> blog post;

- Support in safety-management of electrical high-voltage propulsion-systems and wireless charging of utility vehicles; definition of system boundary, functions, decomposition; hazard analysis, ASIL, requirements-capturing and safety planning acc. ISO26262 and IEC61508 (Germany);

- Simulation-based computation of diagnostic procedures incl. automatic virtual fault-injection procedures to optimize the rule-based onboard-diagnostics for chassis electronics of upper class passenger cars (Germany);

- Project coaching and onsite training for modelbased generation of diagnostic troubleshooting procedures for mechatronical parts incl. ECUs of heavy truck systems (Sweden);

- Application of modelbased diagnosis and automatic generation of troubleshooting procedures of a truck Diesel engine exhaust system, incl. several onsite analysis, test and validation activity periods (US);

- Advanced analysis of failure effects/FMEA for the pneumatic level control of a heavy load truck and of electronic steering system of construction vehicles, covering models of ECU, wiring, actuators and sensors (Sweden);

- Development of reusable virtual functional components incl. fault mode descriptions and automated generation of high-quality troubleshooting sequences for workshop-diagnostics of passenger cars (Germany);

Ready to benefit from this experience in your Automotive-project? – Get in contact now!

Aviation:

Aviation:

- Project coaching and onsite training for evaluation of modelbased methods in Aircraft system engineering incl. safety- and diagnosis-centered tasks (Brazil);

- Pilot study for new modelbased method for optimized layout and electrical load analysis (ELA) of aircraft onboard network topologies and simultaneous testing of HW/SW specification for automatic system reconfiguration, considering all component faults (France/EU);

- Contributions to new approaches for ILS (Integrated Logistic Support) and IVHM (Integrated Vehicle Health Management) to combine various diagnostic techniques and documentations into interactive simulation-based solution (Sweden);

- Evaluation of new methods of diagnosing and monitoring of aircraft systems to reduce the NFF (No Fault Found)-rate e.g. on a flight control system and a aircraft fuel pump system (EU, US);

- Automation of Requirement-Driven Design: developmemt of advanced software module for automatic or interactive optimization of Fly-By-Wire-system-topologies, considering weight-, reliability- and safety-constraints incl. automatic generation of RBDs (Reliability-Block-Diagrams) and Fault-Trees (Germany);

- Support in project for fault coverage analysis of the BITE software and Hidden-Fault-Detection of the A380 smoke detection sub-system in early phases of specification (Germany/EU);

Ready to benefit from this experience in your Avionics-project? – Get in contact now!

Defence:

- Availability-/MTTR-driven architecture analysis and optimization in early design phases/PSSA of a generic launcher system (Germany; see also separate blog article);

- Support in hazard analysis, tracking and documentation, incl. risk mitigation, E/E/PE-analysis, Preliminary FTA and Final FTA, of a land vehicle system acc. to MIL 882 and IEC 61508 for system and operational risks (Germany);

- Modelbased tool-supported effectivity-analysis of the actuator control system of an UAV (Germany/EU);

- Reliability analysis of safety functions of a missile flight control system, incl. automatic double-fault-FMEA, down to board level (Germany/EU; see also separate blog article);

- Pilot modeling project to optimize the availability of a military ship propulsion system over multiple operation phases (Sweden);

Ready to benefit from this experience in your Defence-project? – Get in contact now!

![SOFIA with open telescope doors; by NASA/Carla Thomas [Public domain], via Wikimedia Commons](//upload.wikimedia.org/wikipedia/commons/thumb/7/7c/SOFIA_with_open_telescope_doors.jpg/512px-SOFIA_with_open_telescope_doors.jpg) Space:

Space:

- Modelbased analysis and diagnostic evaluation of the Secondary Mirror Assembly (SMA) of the NASA/DLR-funded Airborne telescope SOFIA;

- Development of a component-oriented thermo-hydraulical library and customer training to analyze the cooling system of the ESA-funded COLUMBUS space laboratory (Germany/EU)

Ready to benefit from this experience in your Space-project? – Get in contact now!

Plant and Machinery:

- Analysis support and coaching on diagnostics, fault propagation and reliability of a dynamic air handling unit (Ireland);

- Pilot project for improved diagnosis of high-speed roll system, covering mechanical, electrical and thermodynamical parts of paper mills (Germany);

- Evaluation of tool-based requirement-definition in product development and to support the safety-process and SIL (Safety Integrity Level)-determination according IEC61508 in process plant development (Switzerland);

Ready to benefit from this experience in your Machinery-project? – Get in contact now!

Medical Devices:

(new field of engangement)

- Member of the “Together against Covid“-initiative to support open-source development of urgently needed devices in the 2020-Covid19-pandemy (e.g. lung-ventilators and PCR-testing device), mainly from the safety-viewpoint; participation in the Pan-European Hackathon “#EUvsVirus 2020“.

- Participation in conferences and exhibitions (e.g. MedTecLive)

- Business development and networking around generic SW platforms and applications projects (refurbishment as well as new developments) of safety critical devices (in behalf of partner)

Ready to benefit from this experience in your Medical-Devices-project? – Get in contact now!

![]() (*) In case of special needs in terms of expertise and availability, we have a strong partner to support your project on short notice – with certified high-quality processes up to CMMI/5!

(*) In case of special needs in terms of expertise and availability, we have a strong partner to support your project on short notice – with certified high-quality processes up to CMMI/5!

![SOFIA with open telescope doors; by NASA/Carla Thomas [Public domain], via Wikimedia Commons](http://upload.wikimedia.org/wikipedia/commons/thumb/7/7c/SOFIA_with_open_telescope_doors.jpg/512px-SOFIA_with_open_telescope_doors.jpg)